Ansys Autodyn

Simulate short duration, severe loadings

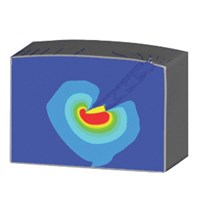

Ansys Autodyn simulates the response of materials to short duration severe loadings from impact, high pressure or explosions. It is best suited for simulating large material deformation or failure. Autodyn provides advanced solution methods without compromising ease of use. Complex physical phenomena such as the interaction of liquids, solids and gases; the phase transitions of materials; and the propagation of shock waves can all be modeled within Autodyn. Integrated within Ansys Workbench with its own native user interface, this program has for decades led the industry in ease of use, enabling you to produce accurate results with the least amount of time and effort.

Autodyn's range of technologies means that you can model solids with Lagrangian elements, and liquids with Eulerian and SPH (smooth particle hydrodynamics), so you can capture every type of event with the most appropriate technology. Multiple solvers can be used in one model, and the interactions between the various domains can be modeled for efficient, accurate results.