Consulting Summaries

Computational Fluid Dynamics (CFD)

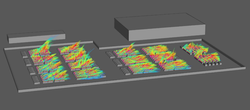

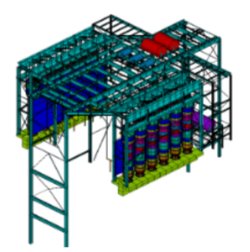

Battery Energy Storage Systems

Objective: Ensure BESS operates below threshold temperatures while at critical distribution loads.

Impact: Mitigated site failures during hot summer days, fines due to contractual performance issues and post-construction retrofits.

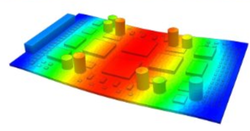

Electrical Enclosure

Objective: Ensure enclosure stays within warranty and threshold temperature ratings during standard and peak operation.

Impact: Improved thermal margins during worst-case conditions without time-consuming testing while mitigating warranty exposure and protecting brand recognition.

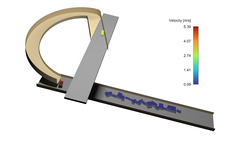

Water Treatment Tank

Objective: Ensure proper exposure time of chemicals within the waste-water for adequate disinfecting prior to tank construction.

Impact: Showcased tank would meet the required exposure times while maximizing total throughput of the system for increased output metrics.

25,000ft Data Center

Objective: Assess rack and room-level airflow characteristics under critical IT loading conditions to avoid hot-air recirculation, equipment overheating and excessive room pressurization.

Impact: Mitigated rack failures and equipment deration to ensure IT infrastructure efficiency and uptime.

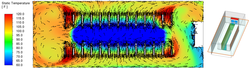

Welding Facility Fume Extraction HVAC

Objective: Compare air dispersion within the space given various ducting strategies to uncover the most effective means of removing weld fumes in a facility HVAC upgrade.

Impact: Produced a duct layout resulting in 40% less weld fume concentration with lower ACH requirements, thus creating a safer environment with lower ongoing utility costs .

Finite Element Analysis (FEA)

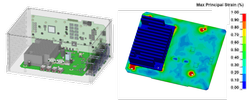

PCB Board Shock and Vibe

Objective: Compare various packaging techniques to ensure PCB will withstand typical shock or vibrational loading conditions during transit.

Impact: Anticipated and addressed failure modes non-destructively while avoiding potential for shipping damage and costly replacement parts.

Structural Platform Seismic Loading

Objective: Assess structural integrity of proposed platform design prior to finalizing construction documentation to ensure compliance with ASCE 7 criteria.

Impact: Simulation-driven design modifications resulted in code compliance and improvement in construction simplicity and cost reduction.

Enclosure Drop Test

Objective: Ensure that the modularized system can survive a 5-ft drop during installation and maintenance procedures given the weight of the onboard heat sink.

Impact: Illustrated the root-cause of a PCB fracture during impact along with the enclosure support modifications needed to address and alleviate future risk of failure.

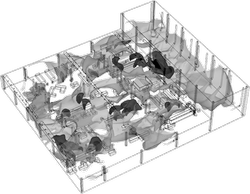

Package Handling Line DEM

Objective: Use physics-based modeling to ensure, with 99% confidence, products would neither bind nor collide given the proposed line layout and speeds.

Impact: Validated package movement efficiency with 99.7% confidence, thus mitigating damaged product and expensive line fabrication retrofits.

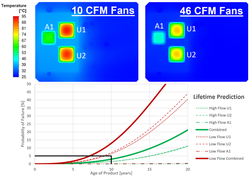

Electronics Reliability of GPU/CPU Enclosure

Objective: Uncover the enclosure design strategy needed to ensure the thermal and structural product lifespan exceeds 10 years with 95% certainty.

Impact: Achieved a 12-year life span prediction given an informed redesign of support structures and fan size/locations while reducing BOM cost and time to market.

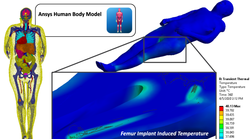

Electromagnetic Field Simulation (EMAG)

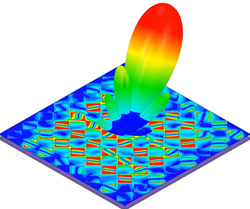

Antenna Design

Objective: Optimize antenna design features and placement for proper match across band of operation and to maximize antenna gain/efficiency.

Impact: Identified optimal design with 60% fewer prototypes and stronger understanding of antenna performance.

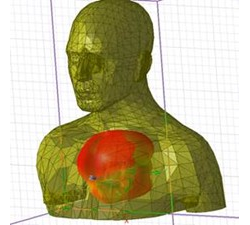

Implant BLE Antenna Range Optimization

Objective: Optimize antenna gain and impedance matching to minimize transmission losses through human tissue.

Impact: Achieved embedded BLE transmission link greater than 1.5m with refined antenna structure.

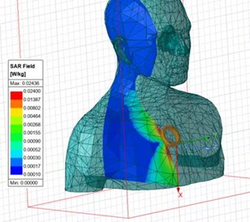

Implant Charging SAR Analysis

Objective: Represent real-life implant charging scenario and confirm Specific Absorption Limit (SAR) within allowable safety limits.

Impact: Regulatory submission supported by simulation results given the understanding of charger misalignment impacts on power transfer efficiency and tissue heating.

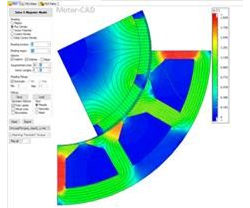

Electric Machine Optimization

Objective: Optimize existing motor design to achieve greater speed/torque output.

Impact: Doubled rated power output with minimal increase to motor size while also increasing overall motor efficiency by 12% across expanded operating range.

Wireless Transmitter MRI Compliance

Objective: Gain confidence in implant’s performance against ASTM F2182 (RF heating) and ISO 10974 (Torque from MRI magnetic field) to ensure patient safety.

Impact: Avoided costly redesign of neuromodulator device and delayed product design schedule.

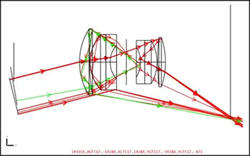

Optics & Photonics

Optical Assembly Stray Light Analysis

Objective: Confirm cross talk between optical fibers caused by stray light scattering/diffraction was below 10 dB to avoid performance degradation.

Impact: Validated feasibility ahead of design freeze while mitigating interference that would produce signal distortion, reduced data rates and communication failures.

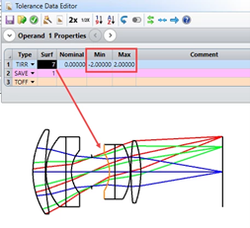

Laser Controller Module

Objective: Conduct tolerance analysis on the optical mounts DOF to properly align lasers and produce a collimated beam.

Impact: Eliminated physical testing costs, reduced mirror fabrication cost by 15% and introduced a systematic workflow repeatable for other modules.